Patterson Cheney Isuzu Pakenham

Enhancing Traffic Flow and Pedestrian Safety for Patterson Cheney Isuzu Pakenham

The newly developed Pakenham Isuzu Trucks, a commercial automotive facility in Melbourne, required a comprehensive safety solution to manage heavy vehicle movement and pedestrian traffic. With automotive safety as a priority, the project team sought a reliable partner to implement critical safety solutions tailored to the site's needs.

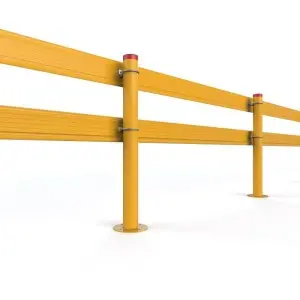

Tasked with providing cutting-edge commercial automotive safety product solutions, Barrier Group installed a range of safety rails, speed humps, wheel stops, and bike racks.

This case study details how Barrier Group facilitated a thorough safety product implementation and guaranteed secure vehicle and pedestrian traffic at the new Patterson Cheney Isuzu Pakenham.

- Location: Pakenham, Victoria

- Complete: December 2024

- Visit: https://www.pattersoncheneytrucks.com.au/pakenham/

The Problem

With automotive safety at the core of the project, the facility required a strategic safety plan that accounted for high-traffic areas, vehicle manoeuvrability, and pedestrian accessibility. The objective was to create a predictable and organised environment, reducing potential risks while maintaining smooth traffic flow.

The Barrier Group team focused on being helpful and making it a communicative process for our installation team to ensure the smoothest installation possible; every decision about this commercial automotive safety solution for Patterson Cheney Isuzu Pakenham was made with safety expertise in mind.

"This project was primarily focused on prioritising safety. Leveraging our wide array of safety products, we aimed to contribute to this project by providing this commercial facility with practical suggestions and options that lead to positive safety outcomes." - Barrier Group

The Solution

With mindful planning over a four-month period and a tender process in place, the project for the Isuzu Pakenham was meticulously crafted through collaboration between the architect and the property owner. This collaboration laid the groundwork for determining the layout and design of the required safety products and their placement across the site.

Barrier Group's role focused on delivering a comprehensive safety solution, including the installation of W-Beam Guardrail, PR Rail, Rib Rail, Speed Humps, and Rubber Wheel Stops. These installations were executed with the expertise of our factory-backed installation team, supported by detailed site visits and consultations.

While the architect determined the design and layout in collaboration with Patterson Cheney Isuzu Pakenham, Barrier Group's internal design team demonstrated significant flexibility in adapting product specifications. This adaptability ensured that our safety product solutions were seamlessly integrated with the site, avoiding interference with existing drains, poles, and lighting towers.

The Challenges

Given that Patterson Cheney Isuzu Pakenham was anticipated to experience significant vehicle and foot traffic once operational, Barrier Group needed to function as both a guide and collaborator on the project.

One challenge involved site infrastructure elements, such as lighting towers and gutters, which required adjustments to the placement of safety products. The Barrier Group product solutions and installation team managed these modifications efficiently, ensuring the installation process remained on schedule.

Client Response

"They've been no problems. We worked with Barrier Group to ensure all the safety products were ready when we needed them and have been exceptionally helpful along the way. They've been willing to do a couple of extra things to make the installation as smooth as possible. I'd recommend Barrier Group to other people and potentially use them on our next project!"

- Site Manager

Trusted by Australia's Largest Brands for Workplace Safety Solutions. Could you be next?

Subscribe to stay connected with Barrier Group and discover cutting-edge safety solutions, updates, and industry insights!