Barrier Group helps you navigate machine safety standards in Australia.

Machine safety is a critical concern for industries across Australia. Ensuring that machinery operates safely not only protects employees but also helps businesses comply with legal obligations. The AS/NZS 4024 standard series is the cornerstone of machine safety in Australia, providing comprehensive guidelines for the design, operation, and maintenance of machinery. In this guide, we'll explore what AS/NZS 4024 entails, why it's essential, and how Barrier Group can assist you in achieving compliance.

What is AS/NZS 4024 and Why Is It Important?

The AS/NZS 4024 standard, titled "Safety of Machinery," is a collection of guidelines that set out the safety requirements for machinery used in Australia and New Zealand. It aligns with international standards, ensuring that machinery meets global safety benchmarks.

Importance of AS/NZS 4024

Compliance: Adhering to AS/NZS 4024 helps businesses meet their obligations under various State and Federal work health and safety (WHS) acts and regulations. Non-compliance can result in hefty fines and legal repercussions.

Risk Reduction: The standard provides a systematic approach to identifying and mitigating risks associated with machinery, thereby reducing workplace accidents.

Operational Efficiency: Safe machinery minimises downtime caused by accidents or malfunctions, leading to increased productivity.

Key Components of AS/NZS 4024 Compliance

- Risk Assessment and Reduction

Risk Assessment is the foundational step in achieving compliance. It involves:

- Hazard Identification: Recognizing all potential hazards that machinery may present.

- Risk Analysis: Evaluating the likelihood and severity of harm from identified hazards.

- Risk Evaluation: Determining the level of risk and whether it is acceptable.

- Risk Reduction: Implementing measures to eliminate or control risks, following the hierarchy of controls:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- Personal Protective Equipment (PPE)

- Machine Guarding and Interlocks

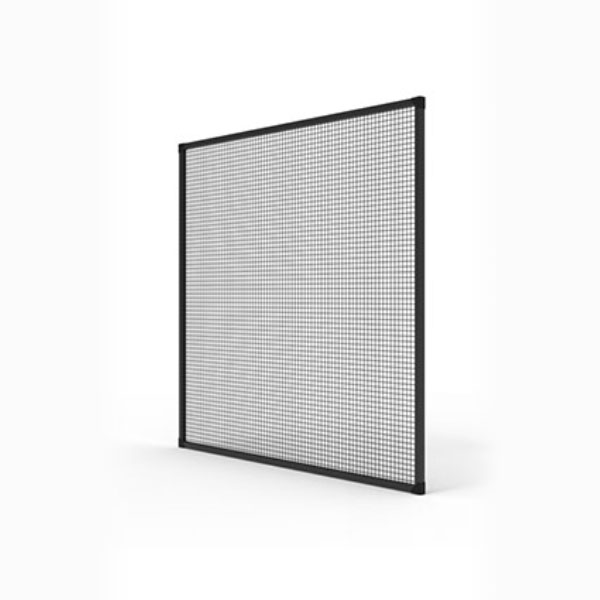

Proper machine guarding is crucial for preventing access to hazardous parts of machinery.

- Fixed Guards: Permanent fixtures that provide a barrier between the operator and dangerous parts.

- Interlocked Guards: Connected to the machine's control system; the machine cannot operate unless the guard is in place.

- Adjustable Guards: Can be modified to suit different tasks while still providing protection.

- Automatic Guards: Activate to protect the operator when a hazard is detected.

- Emergency Stops and Safety Controls

Emergency systems are vital for halting machinery quickly in hazardous situations.

- Emergency Stop Devices: Must be easily accessible and capable of stopping the machine promptly.

- Safety Controls: Include features like two-hand controls, hold-to-run devices, and enabling switches.

- Safe Control Systems

Control systems must be designed to maintain safety even in the event of a failure.

- Fail-Safe Principles: Systems default to a safe state if a malfunction occurs.

- Redundancy: Multiple layers of protection to ensure safety functions are maintained.

- Maintenance and Isolation Procedures

Regular maintenance and proper isolation procedures prevent accidents during servicing.

- Lockout/Tagout Procedures: Ensure machinery is de-energised and cannot be started during maintenance.

- Clear Instructions: Maintenance procedures should be documented and easily understood.

How Barrier Group Can Help You

At Barrier Group, we offer comprehensive solutions to assist you in achieving AS/NZS 4024 compliance efficiently and effectively.

Compliance Consultation

Our experienced team provides:

- Site Assessments: Identify areas where your machinery may not meet standards.

- Risk Assessments: Detailed analysis of potential hazards and risks.

- Compliance Roadmaps: Step-by-step plans to achieve full compliance.

Customised Guarding Solutions

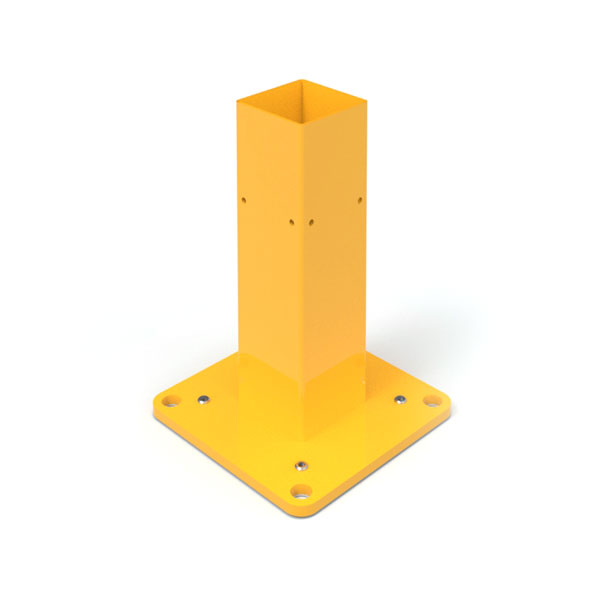

We design and manufacture:

- Machine Guards: Tailored to your specific machinery and operational needs.

- Safety Barriers: Physical barriers that protect operators and equipment.

- Protective Enclosures: For high-risk machinery requiring additional safety measures.

Installation

Professional Installation: Our team installs safety equipment to the highest standards.

Ongoing Support and Updates

Regulation Updates: Keep you informed about changes in standards.

Maintenance Services: Regular check-ups to ensure continued compliance.

About Barrier Group

Barrier Group is a leading provider of industrial safety solutions in Australia. With decades of experience, we specialise in helping businesses achieve compliance with machine safety standards, including AS/NZS 4024. Our commitment to safety, quality, and customer service sets us apart as a trusted partner in safeguarding your operations.

We Can Help You With AS/NZS 4024 Compliance

Contact us today to find out how we can help you achieve compliance with AS/NZS 4024 and enhance the safety of your machinery.